BMC-Leyland Australia

Heritage Group Inc.

© BMC-Leyland Australia Heritage Group Inc.

Sites

By 1973, Leyland Australia employed nearly 6,000 people and occupied many sites around Australia. The size of the Company was comparable to that of many country towns and was served by several staff newspapers beginning with the BMC Reporter, the Review, the BMC Rosette, and lastly, the Leyland City Times.

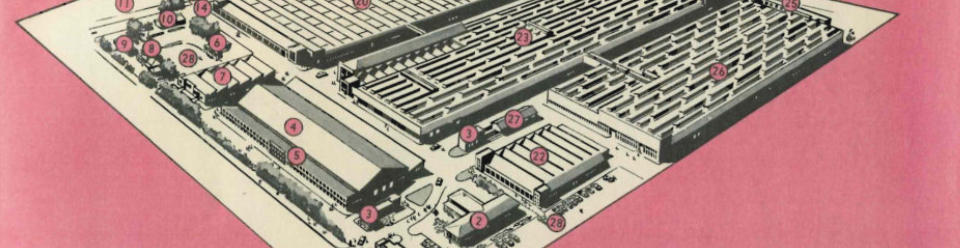

The Victoria Park (Zetland/Waterloo) factory occupied 74 acres with the ability to

manufacture complete vehicles. It comprised four main factories: CKD (later CAB-2), the

Unit Plant, CAB, and the Press Shop. Vehicles were also assembled in CAB-3 when the

Parts and Accessories Division relocated to Liverpool. Nuffield tractors were also

assembled in the Company Garage on the site.

Between 1950 and 1975, 50,000 people collectively spent 130,000 years building motor

cars at Victoria Park. Most employees - typically 5000 at any time were migrants and the

organisation was faced with the 35 languages that they spoke.

Leading hands were selected for their multi-lingual skills;

Employees were grouped to aid communication;

Early instructions were often by sign language; and

Company-run English language classes helped migrants gain English speaking skills quickly.

Meanwhile locals were introduced to exotic smells as imaginative ways were found to heat lunches there being heat sources in

abundance for those with initiative. As expected, many of the migrants worked here for only a few years but they had made a

significant contribution to the company and the company had helped them start in their new country. Further, many thousands of

people were involved in the building of the factory, designing and making the machinery and supplying the thousands of parts

that went into the cars being built here. In all, the number of people involved with the Victoria Park factory exceeded 100,000.

The factory complex developed in the mid 1950s was the only one in the history of NSW where complete cars were

manufactured.

As early as 1958 the cars had a local content of 96%.

One car was built every 4 minutes, each involving the bringing together of 6000 individual parts.

Designed in the 1950's, the plant employed Just-In-Time concepts before the word was coined.

The plant was capable of producing a range of models and variants in any sequence.

It was the only plant where 4, 6 and 8 cylinder engines were made under the one roof.

With the opening of the new administration building in 1968, the official address of the site became: 893-931 South Dowling

Street, Waterloo, NSW.

Pressed Metal Corporation Enfield was purchased by BMC in 1968 and occupied 24

acres. Before the purchase, it was a sub-contract assembly factory. Mini and Moke

production was undertaken at Enfield in 1974/1975. Pressed Metal Corporation Milperra

was an adjunct to PMC Enfield contructing bus bodies on sub-contract.

With the closure of Victoria Park, the Bondi Junction facility became the

Head Office of the Company. Located here were the Board, Sales,

Marketing, Service, Supply and Human Relations. The facility was

eventually closed and moved to a building extension at the Parts and

Accessories site at Liverpool.

Parts and Accessories Liverpool was the central warehouse for supply of

spare parts. Parts and Accessories space was also used as a storage warehouse

for CBU and locally manufactured vehicles.

Engineering Services Moorebank provided product engineering support for

the company. It was also a facility for CBU vehicles, supplying and fitting of

ADR related components to CBU vehicles and Marina damage rectification.

With the closure of the Enfield plant, Land Rover assembly was transferred to

Engineering Services.

Victoria Park

Enfield

Liverpool

Moorebank

Bondi Junction

BMC-LA

Heritage Group

Mobile: 0410 688 886 Email: secretary@bmclaheritage.org.au

© BMC Leyland Australia Heritage Group Inc.

Sites

By 1973, Leyland Australia employed nearly 6,000 people and occupied many sites around Australia. The size of the Company was comparable to that of many country towns and was served by several staff newspapers beginning with the BMC Reporter, the Review, the BMC Rosette, and lastly, the Leyland City Times.

The Victoria Park (Zetland/Waterloo) factory occupied 74

acres with the ability to manufacture complete vehicles. It

comprised four main factories: CKD (later CAB-2), the Unit

Plant, CAB, and the Press Shop. Vehicles were also

assembled in CAB-3 when the Parts and Accessories

Division relocated to Liverpool. Nuffield tractors were also

assembled in the Company Garage on the site.

Between 1950 and 1975, 50,000 people collectively spent

130,000 years building motor cars at Victoria Park. Most

employees - typically 5000 at any time were migrants and

the organisation was faced with the 35 languages that they

spoke.

Leading hands were selected for their multi-lingual

skills;

Employees were grouped to aid communication;

Early instructions were often by sign language; and

Company-run English language classes helped

migrants gain English speaking skills quickly.

Meanwhile locals were introduced to exotic smells as

imaginative ways were found to heat lunches there being

heat sources in abundance for those with initiative. As

expected, many of the migrants worked here for only a few

years but they had made a significant contribution to the

company and the company had helped them start in their

new country. Further, many thousands of people were

involved in the building of the factory, designing and

making the machinery and supplying the thousands of

parts that went into the cars being built here. In all, the

number of people involved with the Victoria Park factory

exceeded 100,000.

The factory complex developed in the mid 1950s was the

only one in the history of NSW where complete cars were

manufactured.

As early as 1958 the cars had a local content of 96%.

One car was built every 4 minutes, each involving the

bringing together of 6000 individual parts.

Designed in the 1950's, the plant employed Just-In-

Time concepts before the word was coined.

The plant was capable of producing a range of

models and variants in any sequence.

It was the only plant where 4, 6 and 8 cylinder

engines were made under the one roof.

With the opening of the new administration building in

1968, the official address of the site became: 893-931

South Dowling Street, Waterloo, NSW.

Pressed Metal Corporation Enfield was purchased by BMC

in 1968 and occupied 24 acres. Before the purchase, it was a

sub-contract assembly factory. Mini and Moke production was

undertaken at Enfield in 1974/1975. Pressed Metal

Corporation Milperra was an adjunct to PMC Enfield

contructing bus bodies on sub-contract.

Enfield

Parts and Accessories Liverpool was the central

warehouse for supply of spare parts. Parts and Accessories

space was also used as a storage warehouse for CBU and

locally manufactured vehicles.

Liverpool

Moorebank

Engineering Services Moorebank provided product

engineering support for the company. It was also a facility for

CBU vehicles, supplying and fitting of ADR related

components to CBU vehicles and Marina damage rectification.

With the closure of the Enfield plant, Land Rover assembly

was transferred to Engineering Services.